Descriptions:

- High-performance CPU core processing: The eight nuclear CPU processing, faster calculation, stronger processing capacity.

- Simple handle structure with push buttons commands: 16 operation mode keys, convenient hand-held at the end, easy to learn, easy to use, simple and fast.

- More data transmission, large-scale storage capacity: completely off-line operation and support a variety of mobile storage transmission methods; 512 mb of internal memory, able to read large storage capacity of the mobile device.

- Intelligent reading glasses processing documents function: AutoNow series products is more intelligent in proofreading document processing, for new processing files, only reading before the first half of operation. And in the reading process, you can also skip the check based on customer needs, which saves the users valuable time to a great degree.

- Intelligent memory function: lost power support and breakpoint processing; not only storage the location process, but also memory the file name, ensure the user continues processing from the point of interruption quickly and accurately.

- Two types of processing mode the choice: high-precision mode and to ensure the machining precision and quality of high-speed mode, which order to ensure the process of efficiency, saving processing time.

- Security monitoring and alarm: Add security alarm system functions and abnormal reminders, such as new zero abnormal tree mark, mobile remote mode safety tips, working beyond the function as the display, greatly guarantee the accuracy and consistency of processing.

- More perfect encryption functions: Hardware and encryption tools, set encryption parameters, cryptography execution time and encryption of important internal processing files, and other functions, editing, prevent delete prevent copying, and information and assets to guarantee secure technical customers.

- Performance Anti-jamming ids greatly increased: Even if a little CE proof, anti-jamming greatly improved.

- Strongest department: auto now the basic version of 8 series of 8 out in the I / O support mouth editing custom functions, the user can completely according to their own editing and defined needs, and can expand to 32 input 32 output; on the basis of 8 nuclear processing CPU, but also for secondary development, for the customer of the special function equipment, special use to add, meet the needs of different sectors, with period of is short, the cost is low, the privacy id good waiting for a feature.

Technical Parameter of RichAuto A18 DSP Controller

| Model | RichAuto A18 |

| Processor | DSP |

| RAM | 512M |

| Display | 3-inch monochrome |

| Communication interface | USB |

| Simultaneous axis | 4 |

| Driving | stepper and servo |

| Resolution | 0.001mm |

| Power failure protection | yes |

| Breakpoint memory | yes |

| Working power | DC 24V |

| Manual Mode | Continuous, step, distance |

| Interpolation method | Line, arc, spline |

| Soft / hard limit | support |

| Maximum pulse frequency | 1MHz |

| Password setup | yes |

| System language | English and Chinese |

Advantage of RichAuto A18E CNC Controller

Compared with NC Studio controller, it has two advantages:

- It controls machine motion independently, no need connection a PC.

- RichAuto A18 price is less than NC Studio.

Application

RichAuto A18E / A18S is always used on 4 axis cnc router , 4 axis rotary cnc machine and 4 axis multi head cnc router.

Quick Details of RichAuto DSP A18E / A18S

- Applicable industry: wood working

- Maximum simultaneous axis: 4

- Display: Three-inch monochrome

- I/O port: 8 input, 8 output

How to Copy the Parameters from The Old RichAuto A18 To the New Controller?

When you replace your old RichAuto A18 hand-held controller with a new one, you will need to copy the parameter settings from the old to the new. Otherwise, the new one isn’t able to work properly.

Here is the instruction for this operation:

- Input a USB flash in your old RichAuto controller and switch on it.

- Follow the guide path here: MENU – SYSTEM SETUP – Backup Data – select backup to U disk – wait for file save, after save is complete, switch off the old RichAuto DSP.

- Take the USB away from the old controller and input it in new one; switch on the new controller.

- Then follow this guideline in new one: MENU – SYSTEM SETUP – Restore Data – select restore from U disk. The parameter copy is over.

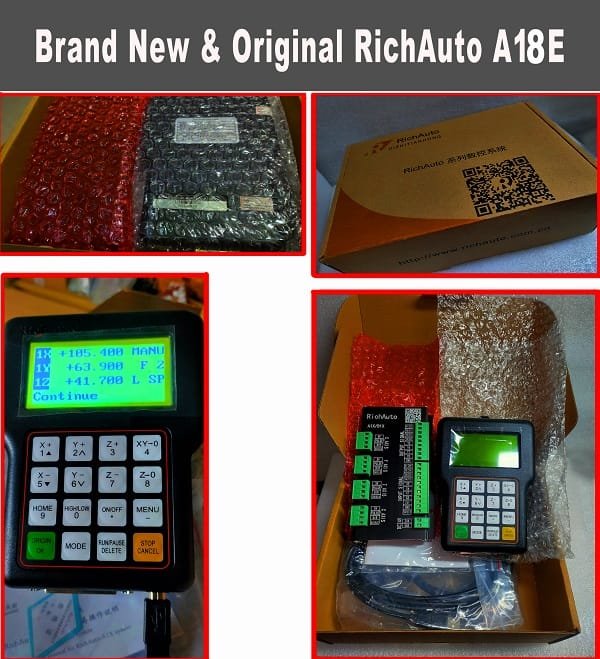

Full Set Packing List of RichAuto CNC Controller A18E / A18S

Please refer to below pictures, it contains 4 parts totally:

- RichAuto hand-held controller A18 – 1 Piece

- Wiring board (8 input 8 output) – 1 Piece

- 50-pin communication cable – 1 Piece (for connection between hand-held controller and wiring board)

- USB data cable – 1 Piece (for connection between hand-held controller and PC)

RichAuto Auto Now A18E / A18S Features

- It is a 4-axis simultaneous CNC controller, real 4 axis motion control.

- The rotary axis can be freely defined with A, B or C.

- The 4th axis can be a normal axis or a rotary axis.

- 8 input and 8 output I/O interface board.

- Support 9 workpiece coordinate, 8 breakpoints save.

- Support both mobile and fixed tool calibration; can set up calibration position and speed, etc.

- Manual high and low-speed switching, fine adjustment, distance and other functions.

- Support XYZ axis driver, inverter, emergency stop, hard limit alarm functions.

- Breakpoint memory and power-down memory.

- Support array, milling plane, zoom, line selection, automatic division special function requirements.

- Stop status and position setup.

Reviews

There are no reviews yet.