The glass transition temperature (Tg) of a printed circuit board signifies the point at which its material begins to change. Exceeding the designated Tg value during operation can cause the board to shift from a solid to a liquid state, which can affect its performance negatively.

Standard PCBs are made with materials that offer a Tg value of 140°C, which can withstand an operating temperature of 110°C. However, this may not be suitable for applications that require extreme-temperature processes, such as automotive, industrial, or high-temperature electronics.

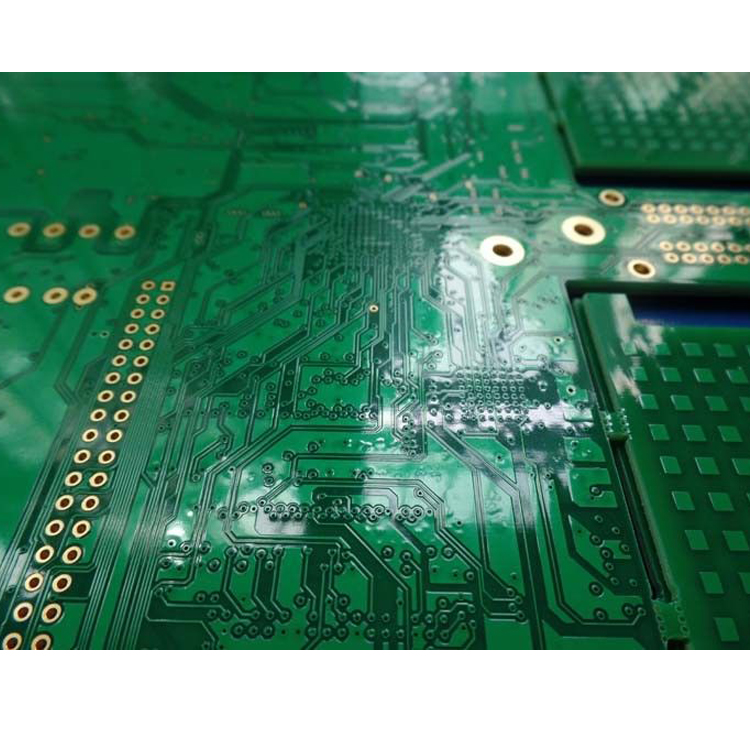

What Is FR-4?

FR-4 circuit board made from flame-retardant fiberglass reinforced epoxy material can offer a much greater level of heat resistance.

FR-4 circuit boards are categorized into four classes based on the number of copper trace layers found in the material: single-sided, double-sided, four, six or 10 layers, and more than 10 layers.

Techonics provides a wide range of high-temperature PCB products and manufacturing services using FR-4 or other high-quality heat and temperature-resistant Tg materials. We can perform high-temperature PCB fabrication for automotive, industrial, and high-temperature electronics applications. We can manufacture High-Tg PCBs with a Tg value of up to 180°C.

A Few of our normally used materials for High-Tg circuit boards production are following:

| Material | TG (DSC, °C) |

Td (Wt, °C) |

CTE-z (ppm/°C) |

Td260 (min) |

Td288 (min) |

| S1141 (FR4) | 175 | 300 | 55 | 8 | / |

| S1000-2M (FR4) | 180 | 345 | 45 | 60 | 20 |

| IT180 | 180 | 345 | 45 | 60 | 20 |

| Rogers 4350B | 280 | 390 | 50 | / | / |