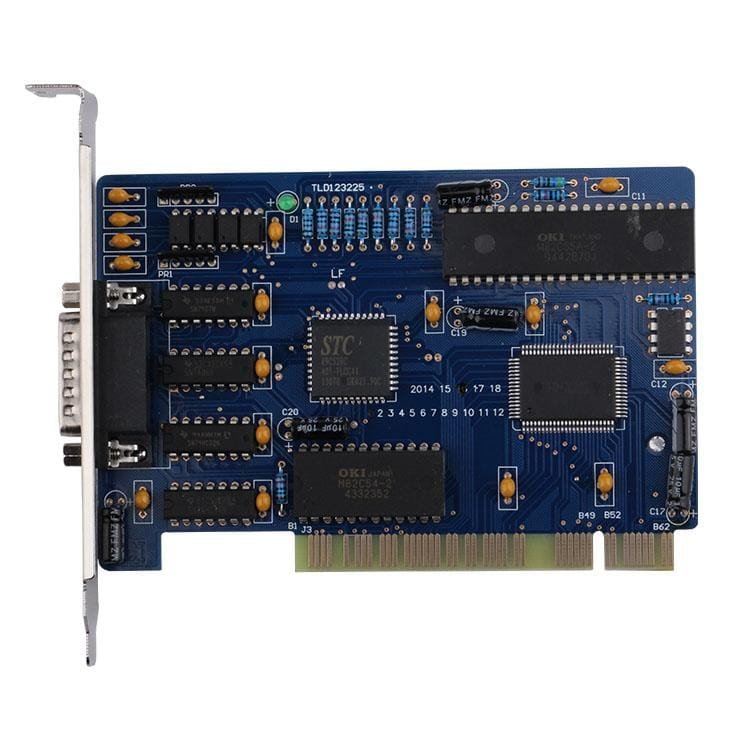

3 Axis PCI NCStudio Motion Card CNC Control Board

Functions:

1) The basic configuration for the three axes of motion. CNC turret support. Automatic processing. Full support for ISO standard G command, HP plotter (HP PLT) format and carved processing (ENG) format.

2) Manual functions. Supports both via the machine input devices, such as handheld devices and other manipulation tools, also supported by the embedded computer input devices such as keyboard, mouse, complete manual operation. Incremental feed function. User to accurately set the feed rate, and can be flexibly adjusted in steps.

3) User data input (MDI) function. Users can enter the G-command line and execute immediately.

4) Advanced processing instruction. Simply enter a few parameters, you can complete end milling, Crochet and other functions.

5) Single-step mode. Users can set up the processing tasks to be performed as a single-step mode, which is the wrong diagnosis and Recovery provides good support.

6) Breakpoint memory, hops perform other advanced automatic features.

7) Save / Restore function workpiece origin.

8) Feed axis precision mechanical origin back (reference point) function.

Automatic tool functionality. These features provide users with great convenience and processing.

9) Feedrate line adjustment In the process the user can adjust the feed rate Minimum to 0, equivalent to suspend processing;. Up to 120%.

10) Smooth speed connection speed characteristics. In general CNC system, the connection speed between two G command is usually a fixed value (for example, a zero or a small value). In the new version of the CNC system, using a unique processing speed adaptive prediction algorithm. The algorithm according to the size of the connection speed, direction, maximum acceleration, and the forward prediction function adaptively determines the current speed of convergence between instruction and the next instruction. Not only greatly improve the processing efficiency (approximately from 30% to 300%), but also improve the processing performance, eliminating the left in the machined surface speed chatter.

11) 3D simulation display function. By a simple operation can be observed from various angles dimensional processing results, which can more accurately and more intuitive understanding of the machining result.

12) Simulation. You can perform fast simulation of the machining program processing can be completed within a very short period of time, while checking for errors and processing procedures, processing the results are satisfactory, and can accurately calculate the actual processing time required.

13) Powerful, flexible keyboard support. The new version supports keyboard operations on very strong. Meet the user’s needs during operation.

14) Log function. The system provides a powerful logging features that help the user to view detailed processing information and system diagnostics.

15) Built-in processing file manager. Users simply save the processed files to the specified directory, Ncstudio Can manage these files in a built-in Manager.

Package including:

1 x CNC studio PCI card

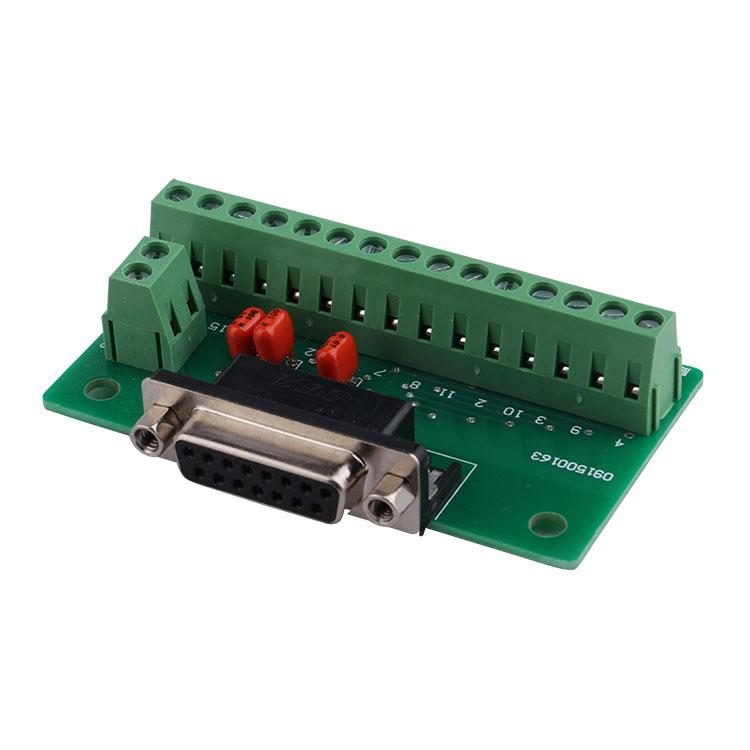

1 x Breakout card with 15 pins.

1 x 3M Date cable

Reviews

Clear filtersThere are no reviews yet.