Description:

Working Scope and Principle:

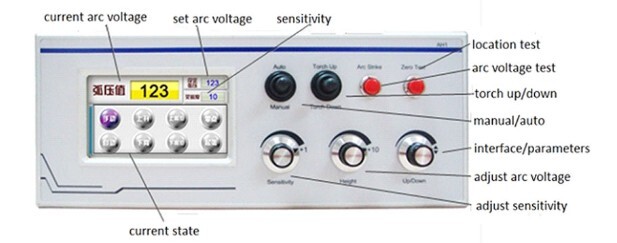

Basic Parameters Diagram

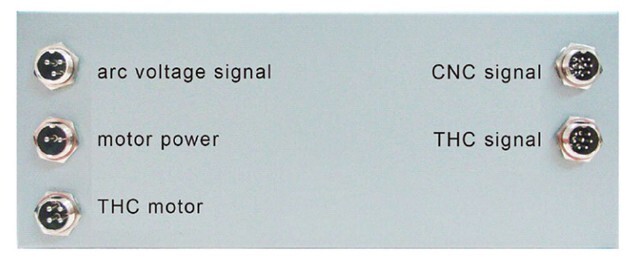

Port Diagram

Technical Parameters:

- Power requirements: DC 24V 1A voltage fluctuations of 10%

- Applicable motor: two-phase hybrid stepping motor

- Motor power: DC 24~40V 4A 10% (AHa-L1)

- Manual adjustment range: 0 ~ 100 mm

- Automatic height control range: 3 ~ 30 mm

- Automatic height adjustment speed: 3000 mm / min (30 ° slope)

- Control accuracy: ± 0.5 mm

- Working environment temperature: -10 ~ 50 °C

- Detection system: plasma arc pressure partial pressure plate, partial pressure ratio of 50:1

Automatic Operation:

Mode 1:

Use location finish feedback and arc strike success feedback of plasma power source, the torch height controller receives the “torch down” signal from the CNC cutting controller, the initial location works first, and after it ends, the “location finish” signal is sent to the CNC, and the CNC stops “torch down” and arc strikes, the CNC receives the “arc strike success” signal from plasma power source, and the cutting starts, after “THC auto delay”, CNC gives “auto” signal to THC, and THC starts to automatically adjust height according to the arc voltage change.

Mode 2:

Use location finish feedback and arc strike success feedback of torch height controller, the torch height controller receives the “torch down” signal from the CNC cutting controller, the initial location works first, and after it ends, the “location finish” signal is sent out to the CNC, and the CNC stops “torch down” and arc strikes, and the torch height controller checks the steady arc voltage signal, then it sends “arc strike success” signal to CNC, after “THC auto relay”, CNC gives “auto signal” to THC, and THC starts to automatically adjust height according to the arc voltage change.

Mode 3:

Not use location finish feedback and arc strike success feedback of torch height controller, some CNC controllers have no functions of “location finish feedback” and “arc strike success feedback, THC receives the “torch down” signal from CNC, and the initial location works when torch moves down, and “torch down” time is longer than “initial location” time,” and torch down ends, arc strikes, and cut. After “THC auto delay”, CNC gives “auto” signal to THC, and THC starts to automatically adjust height according to the arc voltage change.

In auto mode, “set arc” and “sensitivity” can be adjusted by the knob.

Manual operation: adjust the torch height by up/down buttons, initial location and arc strike test.

Reviews

Clear filtersThere are no reviews yet.