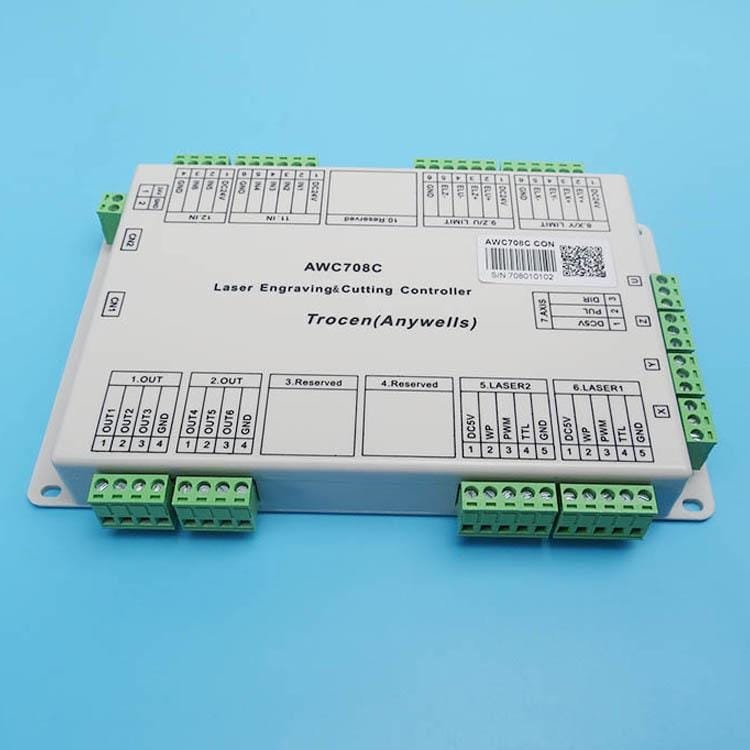

AWC 708 Laser Controller:

For the industrial manufacture of laser systems and DIY laser engraver and laser cutting DIY and upgrade your old laser systems.

Technical parameters:

- Power type maximum motor operation of coordinates laser support field strength of the laser application.

- XYZ U-axis precision.

- DC 24 v, 2A stepper motor.

- Servo motor according to customer requirements ± 0.001mm variety of DC excitation, RF excited CO2 solid state laser laser from 0 to 100%.

- 0.01% continuous adjustable laser cutting machine.

Technical Features:

- CorelDraw and Auto-Cad support

- PWM output or Analog output

- Optical isolation for In / Out data

- Multiple engine configuration

- LIQUID CRYSTALS of the control panel

- Support Dump Drive (no PC needs)

- Recovery memory after power increase

- Support Vector and Raster

- Double control power supply. Leave two lasers in focus simultaneously

- Interface port: USB

- 4 axis control: X, Y, Z, U

- Dual control power supply for PWM or analog control

- Power: DC24V (no need to add 5 v)

- LCD Control Size: 150mm x 100mm

- 128MB of memory on board. It can be run independently from the PC, user-friendly high volume engraving / cutting production.

- 4.3 inches of true color, display, and drive the industry a new direction.

- Support USB2.0 interface, U disk read and write files.

- Mutual support industry advanced double-round cut, greatly saving the processing and processing time of materials.

Reviews

Clear filtersThere are no reviews yet.