Features:

- 7 inches 800*680 dots color LCD.

- Man-Machine-Dialog software and Professional Hot Key design for easy cutting operation, user-friendly as Hypertherm’s EDGE controller.

- Multi-language file system and menu, and the menu can be switched only by one key.

- DSP core can control the machine move in high speed accurately, stably and in low noise.

- Long-distance remote control can control the machine to move forward ,backward, left, right and cutting start, stop and so on (optional configuration).

- Support the EIA code (G code) and various FastCAM、FreeNest、SmartNest、IBE softwares.

- Compact keyboard design and easy to input files.

- Operations such as Proportion Zoom, Rotate, Mirror, Array display, Steel plate angle adjust…..all available and have professional solution in the CNC controller.

- Coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.

- All input and output port type and the number can be customized (normally open or normally closed)

- System Self-diagnosis for easy trouble-shooting.

- All functions and techniques can upgrade online

- Import and export files by single or all files.

- Support the Flame, Plasma, Dusting draw and Demonstration four kinds of mode.

- Flame and Plasma are separated in the control IO ports.

- Support THC, two level preheat, three level pierce in flame mode.

- Plasma arc feedback, positioning feedback, automatically shut down the arc at the corner.

- Support edge cutting. It can save the preheat time for the thick steel plate.

- Movement speed can be real-time acceleration, deceleration.

- According to plate thickness, the cutting speed is automatically restricted by a speed limit in the corner, effectively preventing over burn.

- Dynamic/static illustration of the process, graphics zoom in / out, dynamically tracking cut-off point under zooming state.

- Automatically memorize the working situation and the last cutting point when power off.

- “Cutting offset” function can avoid waste the steel plate when the nesting of the plate is calculated wrong.

- Set up different administration authority and the corresponding password to safeguard the interests of managers.

Details:

- Control Axis:2

- Control accuracy :+/-0.001mm

- Coordinate range:+/- 99999.999mm

- Max pulses : 200kHz Max speed:15000 mm/m

- Max lines of code:150000lines

- Max size of single code file:4M

- Time resolution :10ms

- Working Voltage: DC 24V in put

- Working Temperature:-10℃-60℃. Relative Humidity, 0-95%.

Technical Parameters:

- Axis: 2 (can be customized for three axes)

- Precision control: ± 0.001mm

- Coordinate range: 99999.99mm

- The maximum frequency pulse: 200 KHz; maximum speed: 15 m / min.

- Maximum program line number: 150000

- The largest single program: 6 M

- Time resolution: 10 ms

- Power supply: DC + 24V DC power input

- Working environment system: temperature -10 degrees celsius to + 60 degrees celsius; relative humidity 0-95% without condensation

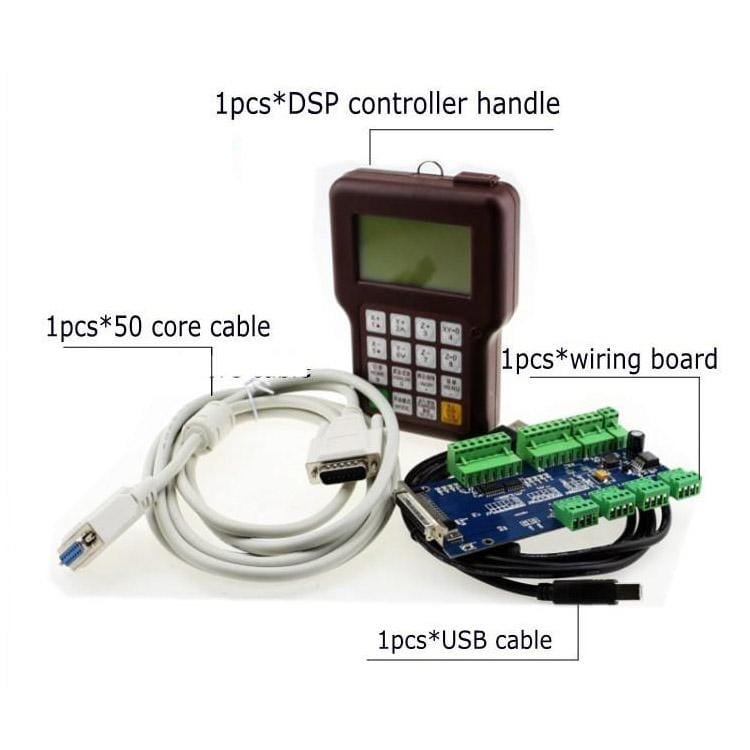

System interface:

- 15 core male two motor drive interface

- 25 core female head 16 photoelectric isolation output, the inverse maximum 300mA of current

- 25 core male 16 isolated inputs, the maximum input current 300mA

- Front panel built-in USB interface, convenient to the user of cutting code transmission

- Extension of entry and exit IO; PWM input port of the analog input port;

Hardware configuration:

- Display: 7 inch high resolution 800 * 480 16000000 colors high brightness LCD screen

- Memory: 2 64 MSDRAM

- User program space: 256 M

- 200 MHZ system clock frequency

- USB: USB1.1 front interface

- Keyboard: electronic PCB film keyboard

- Case: the whole steel frame fully shielded, can really achieve anti electromagnetic radiation, anti-static, anti interference

Reviews

Clear filtersThere are no reviews yet.